E-TANDEM project

About E-TANDEM

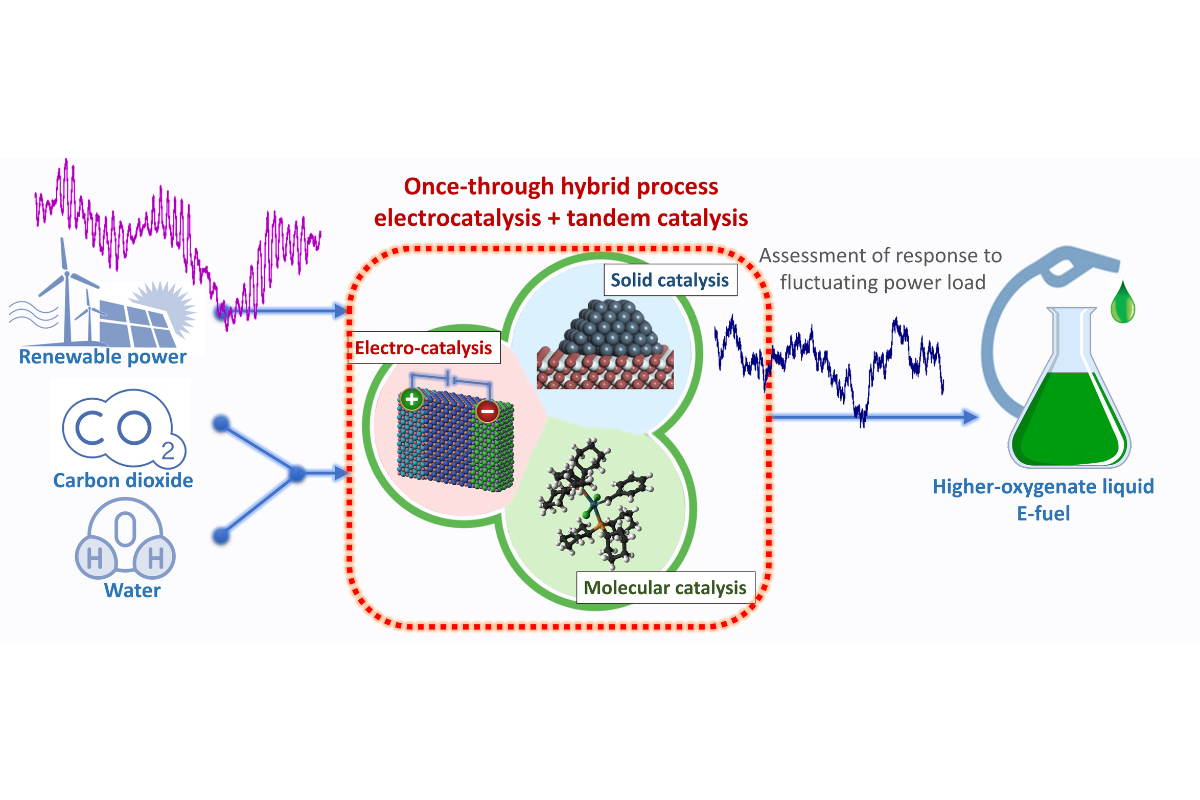

Carbon neutral, high-energy density e-fuels are crucial to de-fossilize long-haul, heavy-duty road, marine and aviation transport sectors. Current e-fuels face hurdles for a swift market penetration due to incompatibility with current ICE fleets and fuel distribution network, and/or non-compliance with fuel norms in force. E-TANDEM aims to demonstrate a new, direct, hybrid-catalysis route for the production of a higher oxygenated diesel-like e-fuel (HOEF) based on higher alcohols and ethers from CO2, water and renewable power only.

Objectives

Develop and validate a process for the direct conversion of CO2 and water, driven by renewable power, for the once-through production of higher oxygenate fuels.

Develop a laboratory-scale (<500 mL) slurry-phase, high-pressure reactor to effectively perform the direct e-syngas conversion by tandem integration of solid Fischer-Tropsch (FTS) and molecular reductive hydroformylation (RHF) catalytic functions, with high withhold rates for both catalyst functionalities.

Validate, at benchtop lab-scale (TRL4), a continuous power-to-fuel process for the production of higher oxygenates (C5+ fraction of aliphatic alcohols and C8+ fraction of aliphatic ether derivatives) with high carbon selectivity and energy efficiency and assess its dynamic response to temporal fluctuations in renewable power input.

Characterize the newly proposed higher oxygenate e-fuel (HOEF), in its two realizations i.e., a mixture of either higher aliphatic alcohols or higher aliphatic ethers, and assess its drop-in characteristics for current-fleet marine and heavy-duty road internal combustion engines.

Assess the technical, economic, and sustainability aspects of the new e-fuel production concept and set the basis for further upscaling developments beyond E-TANDEM.

Concept

E-TANDEM’s ambition is to unlock an efficient and direct production of a new higher-oxygenate diesel-like e-fuel for the marine and heavy-duty transport sectors. This oxygenated fuel is directly produced from CO2 as the sole carbon source, and renewable power as the sole energy input, in a once-through hybrid catalytic conversion process integrating three major catalysis branches: high-pressure electrocatalysis syngas production coupled to a tandem catalytic e-syngas conversion encompassing thermocatalysis with solid catalysts and chemocatalysis with molecular complexes. The project will demonstrate the new e-fuel production process at bench-scale, and assess its capacity to cope with fluctuating energy inputs.

Approach

The project aims to develop a disruptive route wherein CO2, water and renewable power are converted to higher oxygenate e-fuels in a once-through hybrid process integrating three major catalysis branches: “electrocatalysis” is applied in a robust high-pressure CO2/H2O co-electrolysis step to produce e-syngas (H2/CO), which is converted in a single-reactor, slurry-phase process combining “solid thermocatalysis” for linear hydrocarbon synthesis and “molecular chemocatalysis” for in situ oxo-functionalization via reductive hydroformylation. In this process, integration of catalytic functionalities in tandem, alongside an engineered interfacing of high- and lowtemperature conversion steps and energy unintensive membrane separation technologies, offer a blueprint for superior atom and energy efficiencies. Moreover, e-fuel formulation and life-cycle aspects are covered to fully realize the potential of the higher oxygenate e-fuel to distinctively unite excellent combustion properties (high cetane), exceptional reduction of tailpipe soot emissions, advantageous logistics as liquid at ambient conditions and compatibility with current-fleet fuel infrastructure and engine technologies, with emphasis on applications as diesel replacement in heavy-duty marine transport. An exploitation plan will be created together with international stakeholders, to consolidate EU’s capacity to export advanced e-fuel technologies to areas with vast green energy potential.

Results

The results of the E-TANDEM project are documented in reports. The available reports are published here.

Facts and figures

Acronym: E-TANDEM

Duration: 42 months

Start date: 1 November 2022

EC Funding: 3,33 M€

GA: 101083700

Publications

E-TANDEM is conducting research in the field of e-fuel production and will disseminate scientific results to peers in the field by means of scientific publications. All relevant publications will be posted on this page.